Needle systems for overlock machines

Although many modern household overlocking machines can now use normal universal needles, there are still a number of models that require a special needle system. These unique needles are tailored to the specific requirements of the respective model and are not simply interchangeable with other household or overlock needles; after all, perfect sewing results can only be achieved with the right needles. If a specific needle system is required for a particular machine, the machine's operating instructions will provide the relevant information.

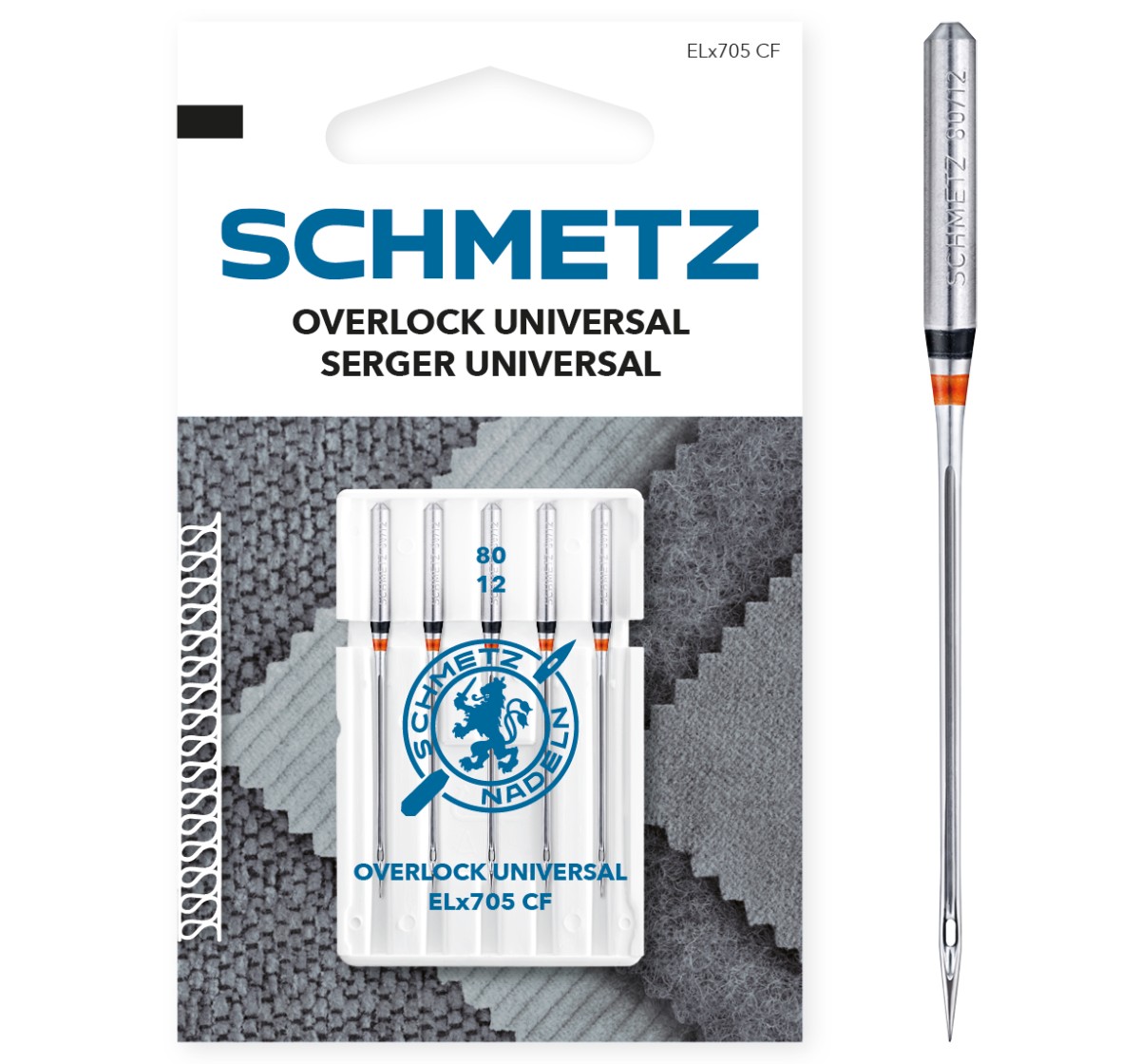

These days, the most common needle systems for overlock machines are:

What is the difference between the various needle systems?

The needle types sometimes have different properties. For instance, they may have different numbers of thread grooves or a different shank flattening or point style. While 130/705 H and HAx1 SP needles have only one thread groove, type ELx705 needles have a second thread groove above the scarf. This supports the formation of chain stitches, such as overlock and coverlock stitches, and ensures that only low thread tension is required to form the stitch. Another special feature of the HAx1 SP needle is that it is closer to the hook due to its special flat shank, which makes it easier for the hook to pick up the thread loop. This prevents skipped stitches, even in highly elastic fabrics. Together with the enlarged eye, the widened thread groove of the HAx1 SP also ensures a smoother thread run. The HAx1 SP is also available in a BLACK version with nonstick coating. This smooth coating ensures that delicate materials are handled with particular care. The Universal Needle 130/705 H and the Overlock Universal Needle ELx705 CF have a slightly rounded point, which can be used to sew most materials gently and without any problems. The 130/705 H SUK Jersey Needle, the HAx1 SP Super Stretch Needle and the ELx705 SUK CF Serger Jersey Needle have a medium ball point, making them perfect for knitted fabrics such as jersey or stretch fabrics.

What happens if I use the wrong needles?

Using unsuitable needles can result in messy seams, skipped stitches or broken needles. In the worst case scenario, your machine could even end up damaged. For this reason, it is essential to always use the needle systems recommended by the overlock machine's manufacturer – and to also take the material and sewing thread into account when selecting your needles. This not only ensures the best possible sewing results, but also prevents potential damage to the machine.

Why is it so important to change your needles regularly?

Over time, needles wear out and may become blunt. Worn needles can lead to messy seams, skipped stitches or even damage to the fabric. Regular needle changes ensure clean and precise seams. Worn needles can also stress or even damage the machine. Timely needle replacement helps to avoid unnecessary stress and wear on other machine parts. Regular needle changes are therefore crucial for the quality of your sewing work, the protection of the material you are working with, and also the longevity of your machine.

Should I replace both needles if one needle breaks?

Even if only one of the needles you are using breaks, it is important to always replace both needles with new ones. This is the only way to ensure that you get optimum sewing results and that your machine works smoothly. After all, the other needle may also be affected by the load and may be damaged or slightly worn. Using a new needle and a worn needle together may result in uneven stitches or problems with material penetration. Replacing both needles ensures a consistent result and good seam quality.