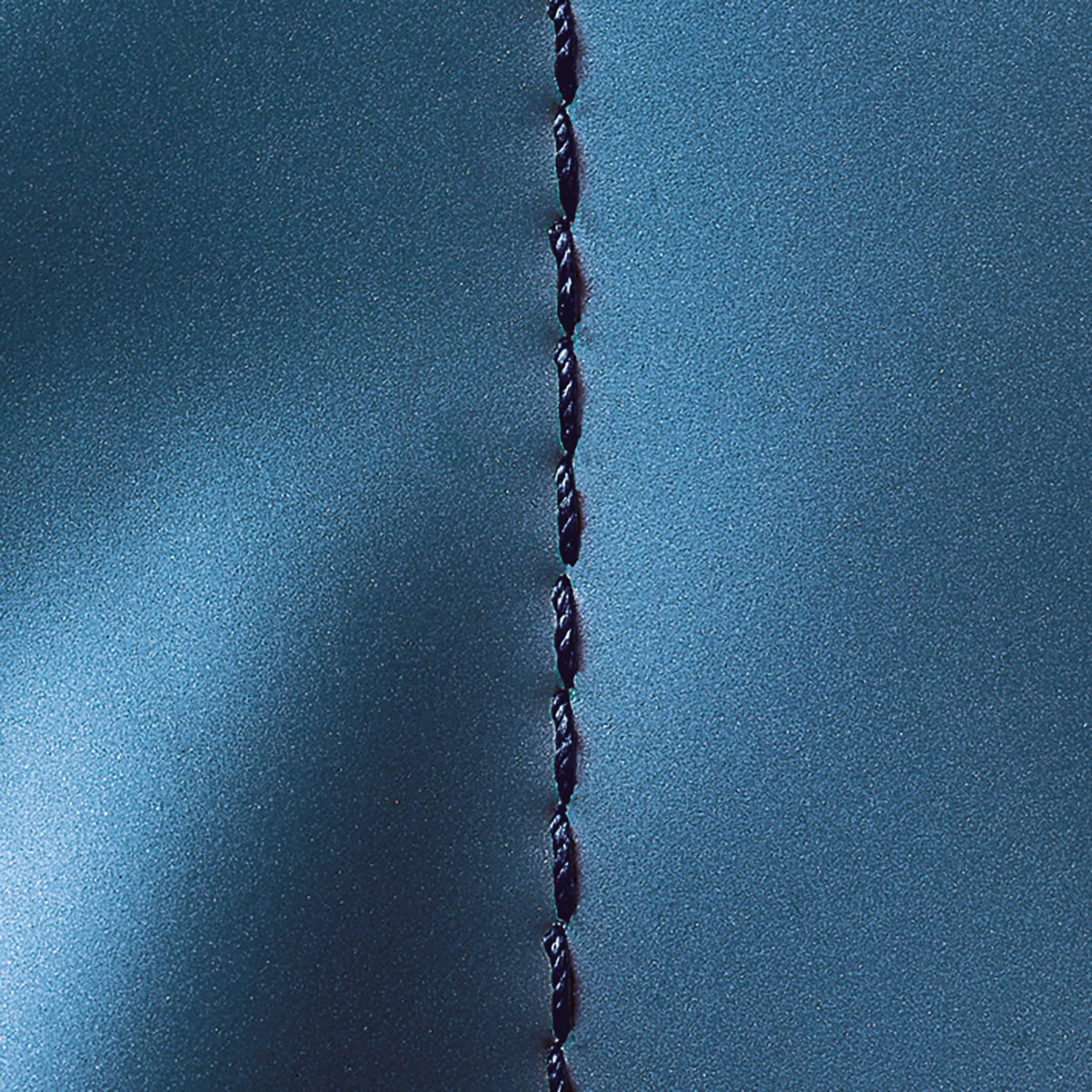

Round points - needles for stitching textiles

The needle point plays an important role in the processing of textiles. SCHMETZ offers you seven different round points for knitwear and woven fabrics, whose special properties contribute to a perfect sewing result:

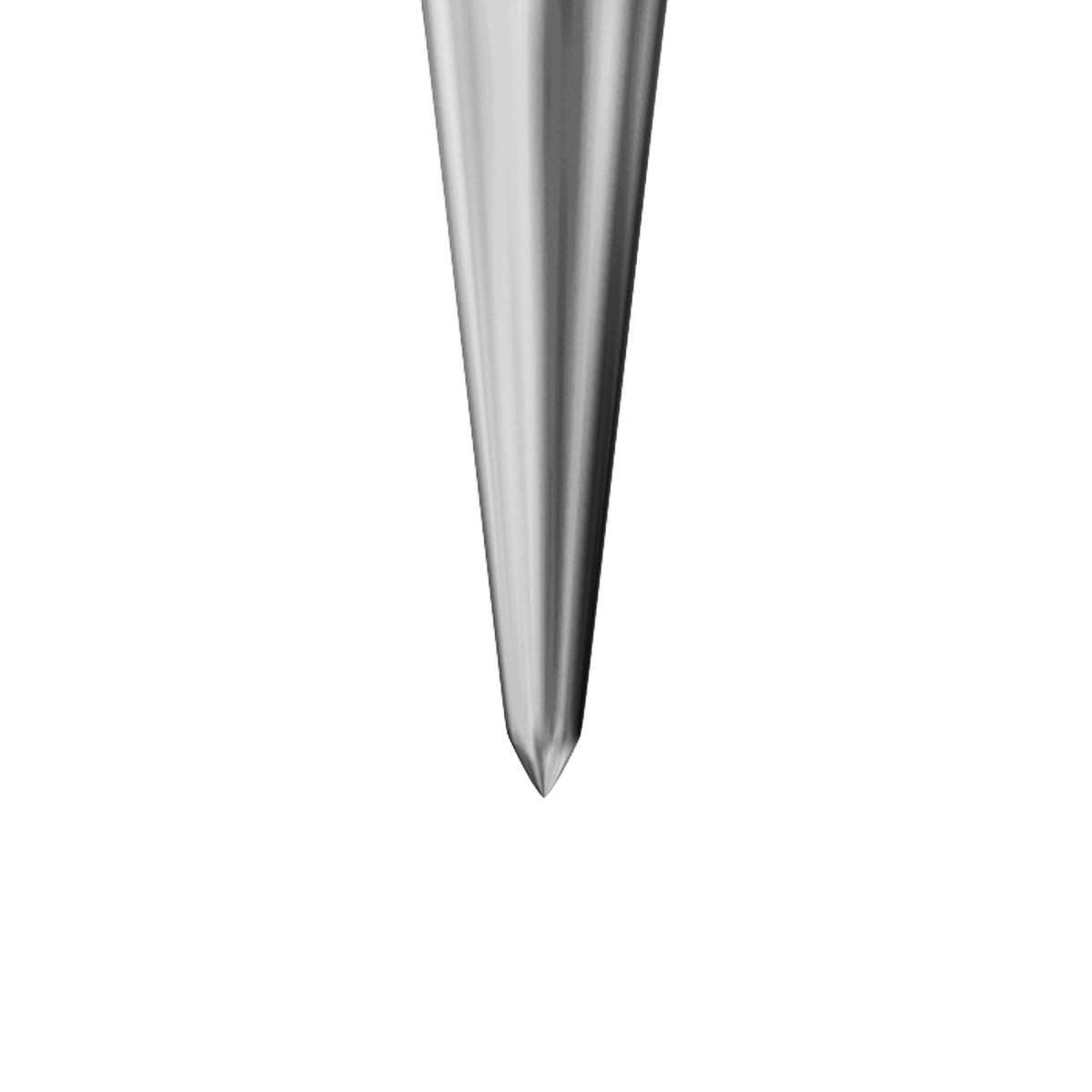

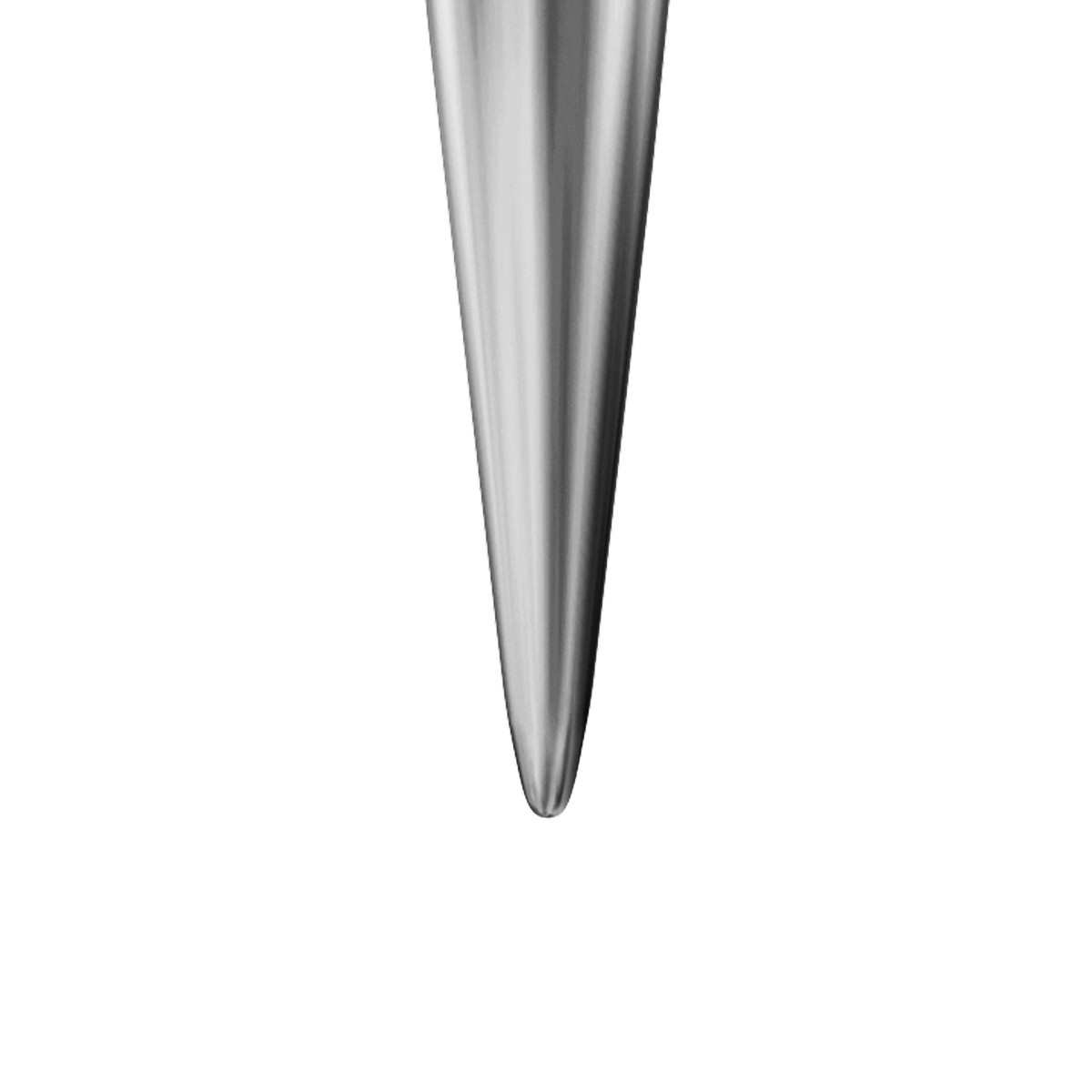

1. Normal round point "R"

The normal round point is the standard point form and has a slim, conical shape. No point supplement "R" is mentioned in the system code.

Applications:

- Light woven fabrics

- Coated materials, heavy woven materials, e.g. tent awnings

- Laminated materials with soft plastic or thin cardboard

- Films

- Leather / textile combinations

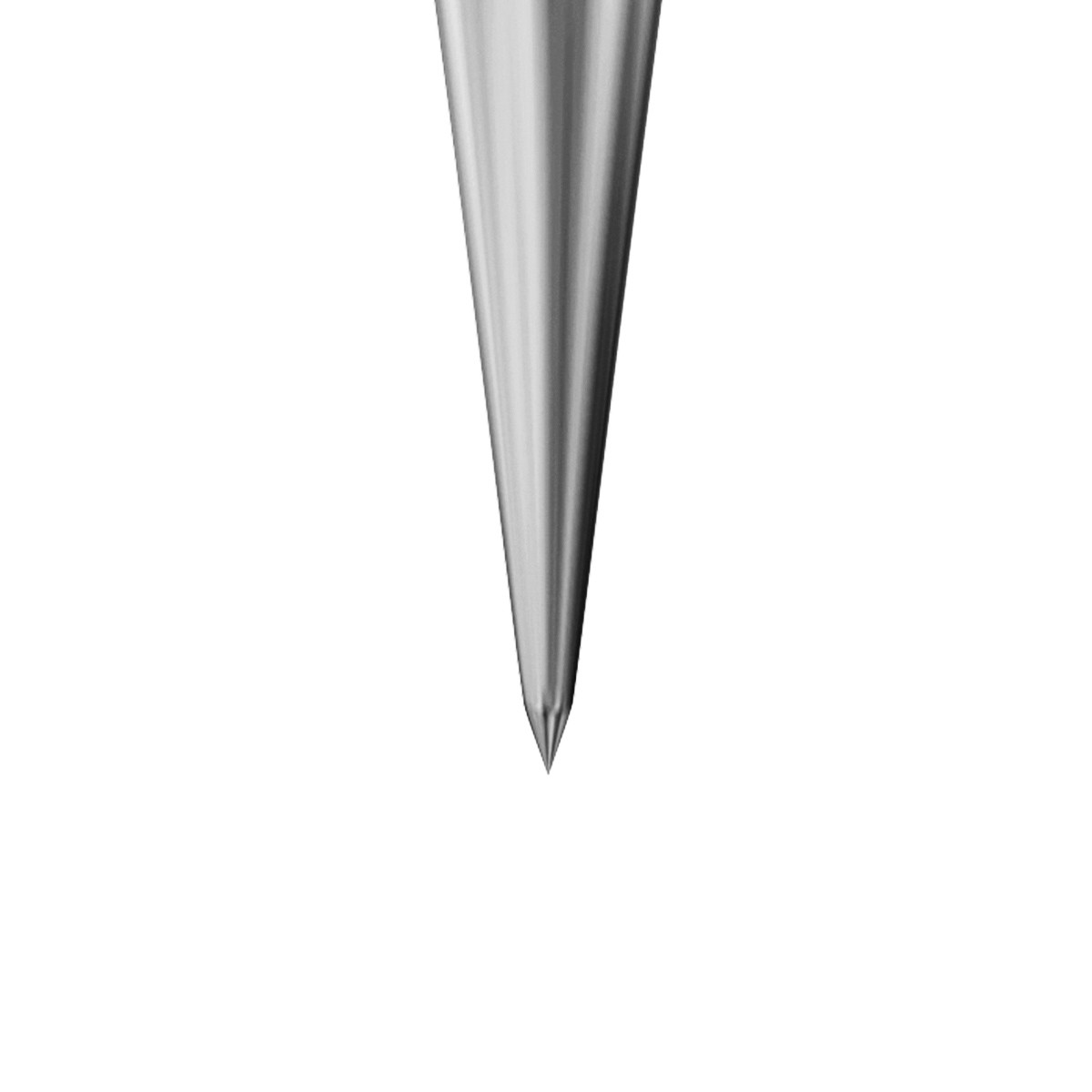

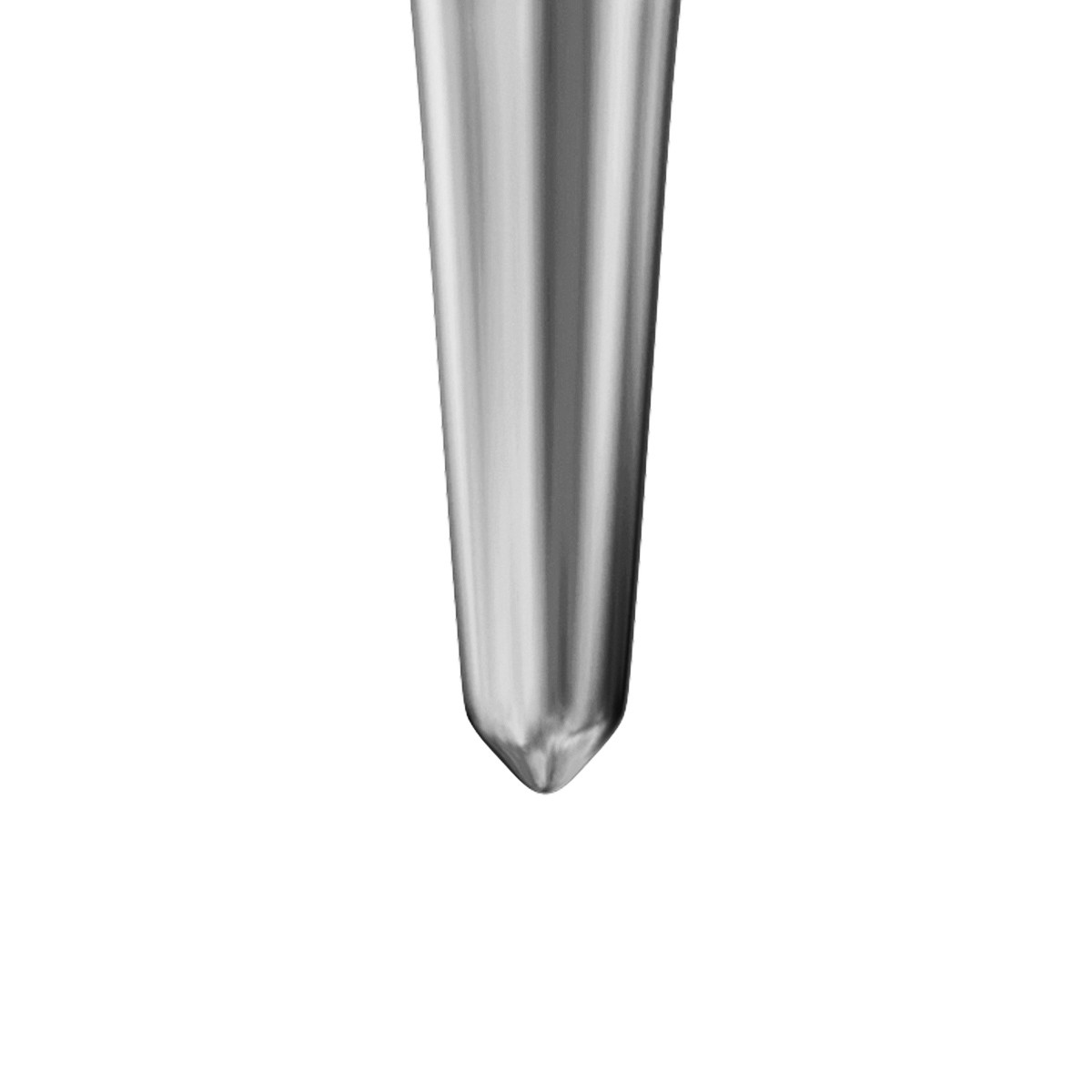

2. Acute round point "SPI"

Needles with a acute round point "SPI" that is very slim, allow accurate piercing of densely woven and coated materials. Additionally, this point shape enables you to get exact seam appearance while avoiding seam puckering.

Applications:

- Very densely woven materials, e.g. microfabrics, silk

- Thin, coated materials

- Thin, smooth materials, e.g. taffeta

- Normal seams in shirt stitching (shirt collars, cuffs)

- Non-covered elastomeric threads

- Manufacture of fur garments and skins

3. Round point with slightly rounded tip "RRT"

The round point with slightly rounded tip is less sensitive to burrs than the normal round point “R”, therefore longer applicable with less damage of sewing goods.

Applications:

- Light to medium woven fabrics

- Fine to medium jeans

- Leather/textile combinations

- Technical textiles

Highlight:

In combination with GO design especially suitable for multi-directional sewing, bartacking operations and embroidery to prevent thread breakage and material damage.

4. Light ball point "SES"

The light ball point displaces woven and knitted threads, directly piercing the spaces and avoiding damage to the material.

Applications:

- Fine to medium knitwear

- Light denim materials

- Light, densely woven materials

- Medium to heavy woven fabrics

- Laminated materials (textile / textile)

Highlight:

Particularly suitable for jersey and sports vests.

5. Medium ball point "SUK"

Needles with a medium ball point are more round than the "SES" light ball point.

Applications:

- Medium to coarse denim materials

- Coarse knitwear

- Manufacture of corsetry

Highlights:

- Best needle for stone- and sand-washed denim grades (particularly in thick needle sizes)

- Best needle for the manufacture of corsetry (particularly in thin needle sizes)

6. Heavy ball point "SKF"

The extremely rounded ball form of this needle permits displacement with coarse, wide loops without piercing the material threads.

Applications:

- Fine elastic materials with covered elastomeric threads

- Coarse knitwear

7. Special ball point "SKL"

Needles with a special ball point "SKL" have a very wide, highly rounded point. This combination achieves greatest possible displacement of the individual threads.

Applications:

- Medium to coarse elastic materials with covered elastomeric threads

- Very coarse knitwear

Highlight:

Best point for sewing Lycra